Total views 3,550 , and 1 views today

Before reading about working of the LNG regasification terminal let’s catch up on something about LNG.

What is LNG?

LNG stands for Liquified Natural Gas. It is Natural gas in liquid form at -162°C. it contains approx. 90% methane, and it is the Cleanest of all the fossil fuels.

Natural gas becomes 600 times lesser in volume when liquified and this is the only reason to liquefy the natural gas by refrigeration process.

By doing this we can transport it in bulk to reduce the transportation cost and for making it affordable.

For reading a more detailed article on LNG please read this article: What is LNG?

In this article we are going to use these two terms frequently LNG and NG, please remember them:

LNG: Liquefied Natural Gas

NG: Natural Gas

What is LNG regasification terminal?

It is the facility where LNG is received or imported from LNG producer countries.

Generally, worldwide all the LNG terminals are located at seashores due to ease of bulk and cheaper transportation facility thorough seaway.

LNG regasification terminal is the place where this liquified natural gas is received using the LNG Cargo ship and stored in LNG tanks for some time by maintaining its temperature and as per requirement or demand, again it is converted back to its gaseous form (We call it Natural gas) using the simple heat transfer method.

Natural gas is a widely used source of energy, and its demand is increasing due to its cleanliness.

Don’t you know why it is called clean? … ok let me tell you …!!!

“It does less carbon content emissions to the atmosphere compared to other fossil fuels, when it is burned in the presence of oxygen or air.”

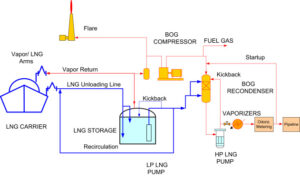

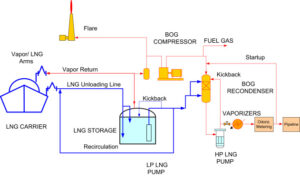

LNG regasification terminal consists of various types of equipment which will make this heat transfer possible.

Equipment used in LNG terminal:

LNG Unloading arm: It is used to unload the LNG from ship to LNG tank facilities. We majorly unload LNG from these arms and that’s why it is termed as “unloading Arm”.

There are major two types of unloading arms: The liquid arm and The Vapor Arm

Let us understand first the purpose of these two different types of arms.

An LNG tank is a closed vessel that is not 100% insulated. so, there is always some heat leak inside the LNG tank.

This heat will vaporize the chilled LNG by increasing its temperature slowly and the increase in temperature will generate gas from LNG which we call BOG (Boiloff Gas).

(LNG has a boiling point at -160 °C so it is very easy for heat to boil LNG and vaporize it that’s why it is called Boiloff gas)

During unloading also this BOG will be generated and this BOG will increase the pressure inside the LNG tank. (Due to a heat leak in the pipeline)

During LNG vessel unloading activity ship will continuously send LNG to the terminal LNG storage tanks and the tank LNG level will increase.

As it is a closed vessel it will push back the BOG towards the roof and will create pressure on the LNG storage tank top plate.

Now during LNG unloading LNG ship is sending LNG from its tank to the terminal tank so the level inside the ship tank will reduce gradually.

And here same as the terminal tank, Ship LNG tanks are also closed vessels so it will generate the vacuum inside the LNG ship tank. (Same as a water bottle, when you suck the water from the bottle, the plastic bottle will get buckled)

So, on the terminal side, we have a tank overpressure problem and on the ship tank side, we have a vacuum problem. So, for solving this problem while doing LNG unloading, we have two types of unloading arms.

So, with a liquid unloading arm ship will send the LNG to the terminal tank and from the terminal tanks, BOG will be transferred to the ship’s LNG tanks using a Vapor loading arm to protect its tank from the vacuum.

LNG storage tanks: As its name indicates it stores LNG.

LNG storage tanks are specially designed to store cryogenic LNG by maintaining its temperature.

LNG storage tank capacity varies from 1,80,000 m3 – 2,70,000m3.

LNG storage tank is made up of a special type of material 9% nickel steel because it does not require high corrosion-resistant material but it requires a material with very low temperature withstand capacity to avoid brittle fracture.

LNG ship unloads LNG into the tanks.

LNG in tank Pumps: This equipment is used to unload the LNG from the tank for further process of regasification. As per the customer demand operator run the pump and remove LNG from the LNG storage tank. then it is sent to the re-condenser.

BOG compressors: As its name suggests it is used to compress the Boiloff Gas generated inside the tank.

This BOG will be sent to the ship while LNG unloading activity and during normal operating conditions it is sent to the re-condenser for converting it back into LNG.

Re-condenser: This equipment is used to re-condense the Boiloff gas generated inside the tank using the heat transfer method.

So, in simple words BOG will be converted back into LNG form again inside the re-condenser.

LNG HP pumps: HP pumps stands for high-pressure Pumps. these pumps are used to push the LNG into vaporizers with high pressure approx. around 100 bara.

So, after this regasification process, natural gas will be pushed into the national NG grid with maintaining the high pressure.

LNG vaporizers: LNG vaporizers are used to transfer the heat of LNG for converting it into NG. there are 4 different types of vaporizers available.

- ORV: It stands for Open Rack Vaporizers. it uses seawater as a heat transferring medium.

- STV: It stands for Shell & tube Vaporizers. It uses glycol water as a heat transferring medium.

- SCV: It stands for Submerged Combustible Vaporizers. It uses heated DM water as a heat transferring medium.

- FDAV: It stands for Forced Draft Air Vaporizers. It uses ambient air as a heat transferring medium.

NG metering: After passing through vaporizers LNG is converted to NG. This re-gasified natural gas is ready for delivery to the customers but how do we know how much quantity of gas we are sending to the customer.

For this purpose, an NG metering station is used. i.e., to measure the quantity of the gas which we are sending to the customer.

National Grid for NG: National grid for natural gas is an infrastructure of the interconnected pipeline through which natural gas is transported to various customers at various locations at constant pressure.

After the metering station, this NG goes into the grid, and then it is distributed to the customers.

The whole process is explained in the Flow diagram please refer to it:

Note: This article is written as the best knowledge of the author, Actual data may differ.

If you have any suggestions please let us know in the comment section below.

For reading more such interesting articles please click here.